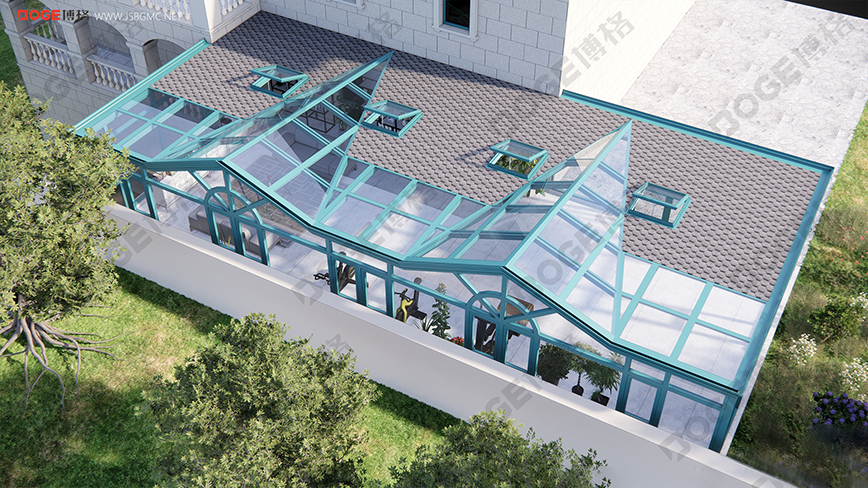

Advantage - Product advantage

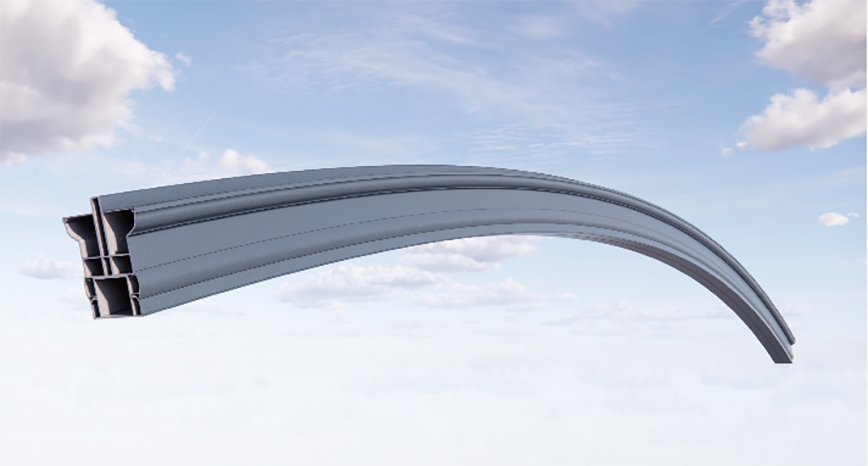

BOGE — Seamless welding

The overall use of seamless welding technology can not only help eliminate mold welds, but also correspondingly improve the accuracy, finish and appearance of parts. At the same time, seamless welding technology implements efficient control during the injection molding process and shortens the mold processing cycle. The arch welding of the main beams of the double bridge and the third bridge is a measure to increase the mid-span height in order to improve, the visual illusion and correct the self-weight settlement.

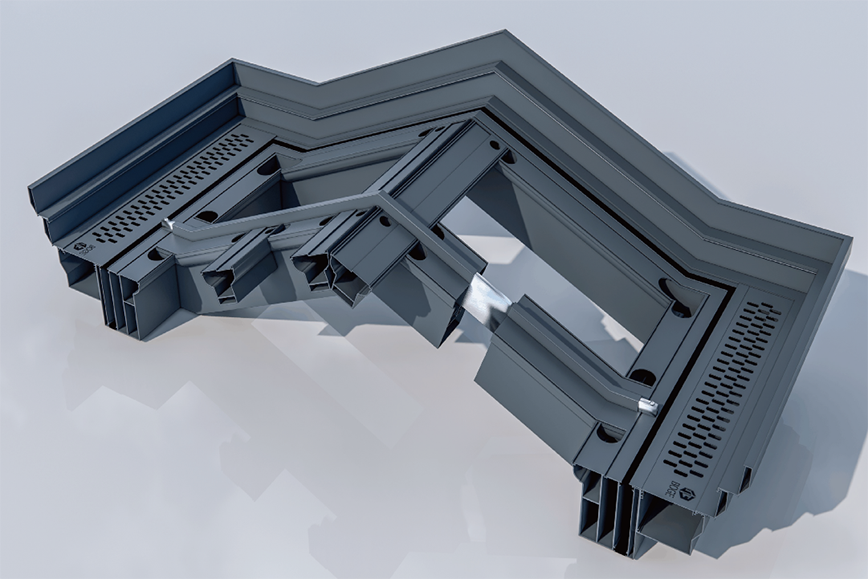

BOGE — Mortise and tenon joint

During the overlap process of the sunroom produced by BOGE, the main load-bearing structure adopts the mortise and tenon overlap process. In the initial stage of load, the gap between the mortise and tenon is squeezed tightly,and obvious slippage occurs between the structural components, indicating that the stiffness is very small at the beginning. As the load continues to increase, the mortise and tenon head will be squeezed tightly with the side wall of the mortise,and friction and normal stress will be generated on both sides to resist the external force. As the bending moment and axial force increase, the mortise and tenon are gradually squeezed tight,which limits the free rotation between the beam and column and improves the structural stiffness.

BOGE — Pre-arch process

Through a horizontal thrust, the bending moment stress originally generated by the load is converted into compressive stress or most of it is converted into compressive stress: The biggest difference between an arch and a beam is the existence of a horizontal thrust. If the point of action and direction of the combined force of this horizontal thrust, the support reaction force and the load acting on it just pass through the axis of the arch, such an arch is a reasonable arch. Borg Sun Room perfectly combines this arch bridge cloud supply technology to achieve a single main beam load-bearing span of 8.6 meters, showing unique technological characteristics.